Rotary solid-liquid separator

Product Usage:

Rotary solid-liquid separator (also known as rotary grid cleaning machine), mechanical grid machine is an advanced water treatment solid-liquid separation equipment, mainly used at the inlet of urban sewage treatment plants, residential community sewage pretreatment devices, municipal rainwater and sewage pump stations, water plants, and power plant cooling water. This equipment is also widely used in water treatment projects in various industries such as textile, printing and dyeing, food, aquatic products, papermaking, brewing, slaughtering, leather making, etc. It is an ideal overnight separation equipment in the water treatment industry.

Structure and working principle:

This equipment adopts a rotary design, consisting of a special shaped plow shaped rake teeth arranged in a certain number of assembly orders on the horizontal axis, forming a rake tooth chain. According to the water flow rate, it is assembled into different gaps and installed at the entrance of the pump station or water treatment system. When the driving device drives the rake tooth chain to move from bottom to top, impurities in the water are picked up by the rake tooth chain, and liquid flows through the grid gap. After the equipment rotates to the upper vertex, the rake tooth chain changes its direction of operation, moving from top to bottom, and the material falls off from the rake teeth by its own weight. When the rake teeth turn from the opposite side to the bottom of the equipment, another cycle of continuous operation begins, thus continuously moving from top to bottom. Remove debris from water to achieve solid-liquid separation.

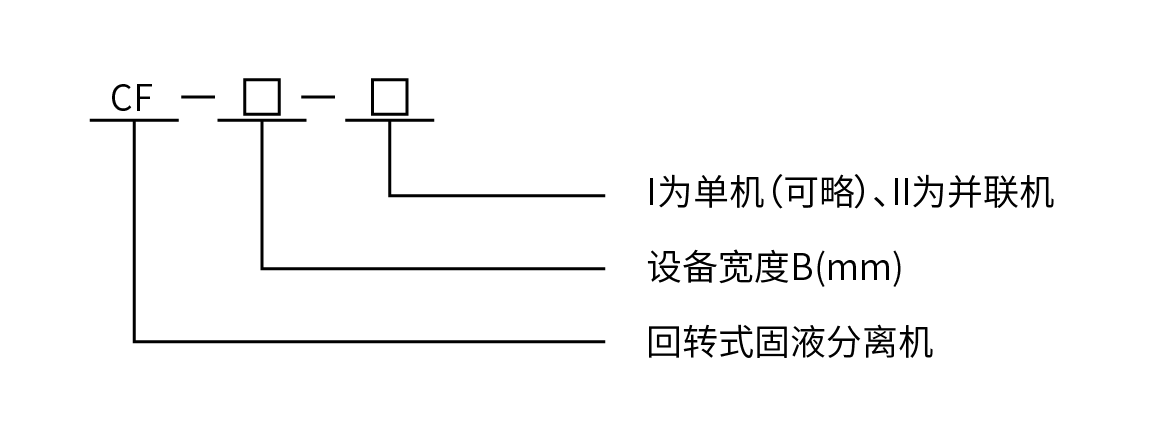

Model Description:

Main technical parameters and installation dimensions table:

Model parameters CF-500CF-600CF-700CF-800CF-900CF-1000CF-1100CF-1200CF-1300CF-1400CF-1500

Equipment width B (mm) 500 600 700 800 900 1000 1100 1200 1300 1400 1500

Channel width B1 (mm) B+100 effective grid width B2 (mm) B-157 foundation bolt spacing B3 (mm) B+200 total equipment width B4 (mm) B+350

Rake tooth clearance b (mm) t=1001 ≤ b ≤ 10t=15010 < b ≤ 50 Installation angle α (°) 60-85

Channel depth H (mm) 800-12000 Discharge port to platform height H1 (mm) 600-1200

Equipment total height H2 (mm) H+H1+1500, rear box frame height H3 (mm) t=100 ≈ 1000t=150 ≈ 1100

Rake tooth operating speed V (m/min) ≈ 2.1 Motor power N (kw) 0.55-1.10.75-1.51.1-2.21.5-3.0

Head loss (mm) ≤ 20 (without blockage) Civil load P1 (KN) 2025P2 (KN) 810 △ P (KN) 1.52.0

Note: P is calculated as H=5.0, and for every 1m increase in H, the total P is P1 (P2)+△ P; T is the pitch of the rake tooth chain.

Main features:

1. The driving device is directly driven by a cycloidal pinwheel or helical gear reducer motor, which has the characteristics of low noise, compact structure, and smooth operation;

2. The rack is a complete frame structure with strong rigidity, easy installation, and minimal daily maintenance workload;

3. There are two types of rake tooth specifications, coarse grid rake tooth pitch t=150mm rake tooth pitch, and fine grid rake tooth pitch t=100mm;

4. The equipment is easy to operate and can be directly controlled locally/remotely for its operation;

5. To prevent accidental overload, mechanical shear pins and overcurrent dual protection are installed to ensure safe and reliable operation of the equipment;

6. When the device width is ≥ 1500mm, in order to ensure the overall strength of the device, a parallel connection form will be adopted.