Yijing Environmental Protection - the leader of China's environmental protection industry, since its establishment in 86 years, has been focusing on the environmental protection water industry, leading the development of China's environmental protection water treatment industry.

With innovation as the growth point, after nearly 30 years of continuous and stable development and professional management, Yijing Environmental Protection has become a group enterprise integrating research and development design, equipment manufacturing, pharmaceutical production, engineering general contracting, water project investment and operation management. It has six wholly-owned subsidiaries and a Swedish joint venture company with total assets of 460 million yuan. It is a provincial key high-tech enterprise, a backbone enterprise of China's environmental protection industry and a governing unit of China Environmental Protection Industry Association. The company has passed ISO9001:2000 quality management system and ISO14001 environmental management system certification.

Yijing Environmental Protection through the promotion of Yijing professional knowledge and advanced technology on a global scale, so that industrial development and environmental protection harmonious coexistence, so as to achieve sustainable development of human beings.

Project background

China's pulp industry has the characteristics of high water consumption and heavy pollution, and is the key industry of pollution reduction in the national "Twelfth Five-Year Plan". In order to speed up the pace of pollution control in the paper industry, in June 2008, the Ministry of Environmental Protection issued the "New Standard for Water Pollutant Discharge" (GB3544-2008). The new standard will significantly tighten the water displacement and emission concentration. The emission standards of pulp manufacturing enterprises, COD limits from 200 mg/l to 100 mg/l; The emission standard of pulp co-production enterprises, the COD limit from 120 mg/l to 90 mg/l; The emission standards of paper enterprises, COD limits from 100 mg/l to 80 mg/l; At the same time, in order to prevent the eutrophication of water bodies and the water bodies that the state needs to focus on protection, special emission limits of pollutants have been formulated.

At present, the traditional domestic pulping wastewater treatment process adopts the method of anaerobic-aerobic chemical flocculation, which can only meet the discharge standard of the old national standard. In order to meet the discharge standard of the new national standard, it is necessary to carry out technical transformation of the existing wastewater treatment system and increase the advanced wastewater treatment process.

The existing advanced treatment mostly adopts Fenton process, but due to its large equipment investment and high operating cost, the promotion of Fenton process in the field of water treatment is limited.

Yijing Environmental protection contact with many universities and scientific research institutions at home and abroad, after thousands of continuous experiments, successfully developed a new pulping wastewater treatment process - FCCS process.

1. Brief introduction of process

The technical core of the process is the oxidized flocculation fluidized bed, which is a new pulp wastewater treatment process developed by the synergistic action of catalytic oxidation, coagulation and adsorption. This process uses a special dosing device developed by itself and a special dosing method created to increase the effective utilization rate of the agent. At the same time, a special oxidation flocculation fluidized bed reaction device is used to reduce the cost and improve the removal rate of pollutants. The process has obtained 3 invention patents of pharmaceutical and process equipment and 1 utility model patent. At the same time, the project is the national 2010 Torch Plan project and the national major technology promotion project.

Process extension

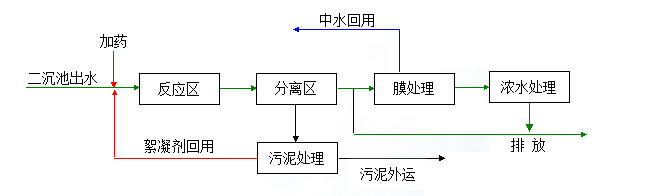

FCCS process + membrane treatment process

Membrane treatment is a mature technology in reclaimed water reuse, and it is one of the main directions in the development of water treatment. Yijing Environmental Protection is now cooperating with Hangzhou Membrane Key Laboratory of the Chinese Academy of Sciences to conduct a pilot test of pulp wastewater advanced treatment and reuse technology, which is implemented in Shandong Rizhao Asia-Pacific Senbo Pulp and Paper Co., LTD.

FCCS process + sludge treatment comprehensive utilization technology

In the existing water treatment process, a large amount of sludge is generated due to the use of water purification materials such as flocculants. At present, there are usually two treatment methods for sludge, one is to discharge it directly into the tank or other open space without dehydration and drying, and the other is to landfill after dehydration and drying and concentration treatment. Of these two methods, the former will have a great negative impact on the environment; The latter is expensive to deal with. Through cooperation with Swedish companies, Yijing Environmental Protection has jointly developed comprehensive utilization technology for sludge treatment. The technology achieves the recycling of aluminum and iron in flocculated sludge through the separation and concentration of aluminum and iron from sludge. At the same time, after the aluminum and iron ions in the sludge are basically recovered, they can be directly incinerated, thus solving the problem of sludge discharge.

This technology has been applied for patent in China, patent number: CN200480032275.8, CN03812055.0.

Operation mode

This process adopts the operation mode of BOO (Build Own Operate), that is, our company is responsible for investment and contract pharmaceutical operation.

Project Case 1

Jinhai pulp and paper industry project introduction

Hainan Jinhai Pulp and Paper Co., Ltd. is a large pulp and paper enterprise with an annual output of 1 million tons of wood pulp and 1.6 million tons of paper. The current sewage discharge standard is below COD100mg/L, but its water consumption per ton of pulp is only 18 tons of water/ton of pulp. The depth of pulping wastewater is relatively high. In order to meet the discharge standards, Jinhai Pulp and Paper invested 120 million yuan in 2009 to increase Fenton process. However, the operation cost is high, and the adoption of the environmentally friendly FCCS advanced treatment process can significantly reduce the cost under the premise of meeting the emission standards.

In 2010, Yijing Environmental Protection proposed a set of FCCS process scheme based on the existing resources of Jinhai pulp after a large number of pilot experiments and a period of pilot experiments at the Jinhai pulp site. After advanced treatment by FCCS process, the COD of the wastewater can be stabilized below 100mg/L, and the operation cost can be effectively reduced, and the sludge volume can be reduced by 30%.

At present, Jinhai Pulp and Paper industry's total investment in sewage treatment is 240 million yuan, and the sewage treatment cost is 9.8 yuan/kg COD. The process transformation plan proposed by Yijing Environmental Protection on the basis of making full use of the existing resources of Jinhai pulp and paper industry requires an additional investment of 20 million yuan, and the cost of process sewage treatment after the transformation is 7.5 yuan/kg COD. The specific investment cost, operation cost and treatment effect after the transformation are shown in the following table.

Project Case 2

Asia-pacific Sembo project introduction

Shandong APAC Sembo Pulp and Paper Co., Ltd. is a large pulp and paper enterprise with an annual output of 1 million tons of wood pulp and 2 million tons of paper. Its water consumption per ton of pulp is 20 tons. The current sewage discharge standard is that COD must reach 100mg/L or less, and it is committed to reducing the COD of discharged sewage to 60mg/L or less in 2013.

At present, the daily treatment capacity of Sembo pulping wastewater is 100,000 tons/day, and the COD of the final effluent after in-depth treatment is below 100 mg/L, which is in line with the current sewage discharge standards of the pulping industry. However, the sewage discharge standard of the pulping industry is expected to be in 2013, requiring the final effluent COD to reach 60 mg/L or less, which requires the transformation of the existing sewage advanced treatment process of Sembo.

After a detailed understanding of the existing process and equipment of Sembo, Yijing Environmental Protection proposed a plan to transform the existing process of Sembo based on the existing facilities and equipment of Sembo through a period of pilot and pilot tests in 2010. After the modified process treatment, the COD of the final effluent can be stabilized below 60 mg/L, meeting the requirements of the new discharge standard.

Project Case 3

Phoenix Paper project introduction

With an annual output of 120,000 tons of pulp and paper, Phoenix Paper is one of the professional manufacturers of bleached sulfate commercial chemical wood pulp with ************, production process and technical equipment ******. At present, the sewage discharge standard of Phoenix Paper industry is that COD must reach 100mg/L or less, but now it is difficult to meet this standard.

In 2010, Yijing Environmental Protection has done pilot and pilot experiments in Phoenix Paper for a period of time, and proposed a set of FCCS process that conforms to Phoenix Paper based on the sewage status and resources of Phoenix Paper. The improved process can stabilize the effluent COD below 60mg/L and reduce the sewage treatment cost to a certain extent. The specific differences before and after process modification are shown in the following table.

Project Case 4

Jin 'an pulp industry project introduction

Sichuan Jin 'an Pulp Industry Co., Ltd. is a large-scale bamboo pulp production enterprise with an annual output of 120,000 tons of bamboo pulp. Its wastewater discharge standard is 100mg/L or less, but the current treatment process used in Jin 'an pulp industry is difficult to meet this discharge requirement.

In 2010, Yijing Environmental Protection conducted pilot and pilot experiments in the Jin 'an pulp industry for a period of time, and proposed a set of FCCS process conforming to the Jin 'an pulp industry based on the sewage status and resources of the Jin 'an pulp industry. The improved process can stabilize the effluent COD below 100mg/L and reduce the sewage treatment cost to a certain extent.